PCBA TECHNOLOGY, PRODUCTS & PROCESSES

SBC services include: PC Board Assemblies, Full Box Builds, HDI, Mechanical Assembly, Cable and Harness, Backpanel Press-Fit or Soldered-in Assembly, Conformal Coating, Potting, Emi Shield Coating, Final Assembly and a wide range of Optical, Electrical, ICT, and Functional testing.

Surface-Mount Technology (SMT)

Utilizing our fully automated Fuji lines SBC can concurrently produce an array of technologies and volumes. SMT is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards. An electronic device so made is specifically called a surface-mount device (SMD). SMD’s have largely replaced through-hole technology, a method of fitting components with wire leads into holes in PC Board’s. Both technologies can be used on the same board for components not suited to surface mounting such as large transformers and heat-sinked power semi-conductors, etc. With SMD technology design engineers have the capability to significantly increase the density of designs.

An SMT component is typically smaller than its through-hole counterpart because it concurrently has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of solder balls (BGAs), or terminations on the body of the component.

Assembling with SMD parts is a standard at SBC down to 0201 part type and up. We also produce smaller devices with engineering review.

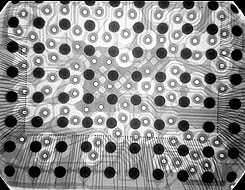

Ball Grid Arrays (BGA’s)

BGA’s are a standard process for SBC. BGA’s components chiefly allow for very high density designs. A ball grid array is a surface-mount packaging (a chip carrier) used for integrated circuits. BGA’s permanently mount devices such as microprocessors to PC Board’s. This technology provides more interconnection pins than can be achieved with a dual in-line or flat package. Correct placement is verified on all product produced at SBC by X-Ray examination.

Through-hole Assembly (THA)

THA is readily done at SBC. This process is one of loading electronic components with leads (axial or radial) into the PC Board’s then soldering by wave or hand soldering equipment. Many circuit designs still incorporate THA components along with Surface Mount Technology (SMT). Here at SBC we have the capability explicitly to handle any component technology available, old or new.

Box Build

SBC also builds assemblies for your end product or produce the entire product including final test, packaging, and order fulfillment as needed. This can be accomplished in as little as 72 hours with components and enclosure materials available. We have extensive experience building complete products/box builds for a wide variety of industries including instrumentation, medical, automotive, power controls, consumer electronics, to name just a few. Our services include full turnkey not only for the electronic assemblies but providing all related metal, plastic, painting, and wiring required to complete the product.

With SBC’s “World Quickest” PC Board Layout to Assembly and Full Turnkey Services we get you to the market place first whether it is through assembly or a full Box Build. Then as production ramps up we provide full support at whatever volume is required with our domestic and offshore capabilities.

Backplanes

SBC has undoubtedly been an industry leader in Backplane technology for over 25 years. What makes Backplanes unique is they typically use Press Fit Connectors. SBC accomplishes this special assembly utilizing the many press fit tools we have available. SBC has the unique capacity not only to assemble Backplanes but build the PC Board Fab as well. Having this dual capability lends greatly to product quality in this tight tolerance assembly. A Backplane is a PC Board used to connect the many circuit boards of a computer or computer system to each other.

Cable & Harness Assembly

SBC produces a wide variety of Cable & Harness Assemblies. These are typically an assembly of cables or wires which transmit signals or electrical power. The cables are attached together by a variety of methods including: straps, cable ties, etc. They are used in electronic instrumentation to maximize space, improve quality, and ease management when extensive wiring is required.

Mechanical & Final Assembly

Following customer specification SBC can complete all Mechanical and Final assemblies. This includes also customer orders: make to order (MTO) or assemble-to-order (ATO). We use a variety of tools and machinery to assemble parts and components into a final product that includes final packaging when required.

Conformal Coating

SBC offers many different types of Conformal Coating including: Silicon, Acrylic, and Urethane. This process provides a protective coating that ‘conforms’ to the circuit board topology. Its function is to chiefly protect electronic circuits from harsh environments that may contain moisture and or chemical contaminants.

Potting

SBC provides this service to improve reliability in adverse conditions. In Potting we completely fill a completed electronic assembly with a solid or gelatinous compound for resistance to shock and vibration, and for exclusion of moisture and corrosive agents. Thermo-setting plastics or silicone rubber gels can be used.

Water Soluble Fluxes

SBC uses a high quality water soluble flux with DI rinse to insure contamination free boards. Flux is a weak acid that removes oxides on PC Board’s that consequently insure solder wetting during the soldering process. This is essential to the soldering process. The use of water soluble fluxes insures they can be washed away, eliminating residue during the final board assembly.

DI Water Closed Loop Cleaning

To support clean completed assemblies Deionized Water (DI) is used in the final rinsing processes. This is especially important to long term PCB reliability. DI water is de-mineralized, and can be considered pure. We use a filtering system to maintain a high quality cleaning system. This system includes a reverse osmosis membrane (filter tank) followed by a special deionization system, which removes remaining ions in the water. The purity of deionized water exceeds the purity of distilled water. During the wash cycle, water is continuously purified by a series of filters. Replenishment is required only to replace water loss due to evaporation and the end result is a contamination free PC Board Assembly.

IPC-A-610 Acceptability Standard for Electronic Assembly

SBC adheres to IPC-A-610 standards of quality during all stages of PCB Design and PC Board manufacturing. This includes visual quality acceptability requirements, acceptance standards of electronic assemblies, and process specifications.

CERTIFIED IS09001

SBC is an ISO 9001:2015 certified company through UL-DQS. South Bay Circuits utilizes ISO 9001:2015 eight fundamental quality management principles to help improve our PC Board Fab, PC Assembly, and Box Build performance. Certificate #: 10000903 QM15

ITAR REGISTRATION

ITAR Registered & CMMC Level 1! We are a manufacturer that builds defense articles with related technical data that can be defined on the United States Munitions List (Part 121 of the ITAR), where we are registered and meets the reqirements of CMMC Level 1.