FIVE STEPS TO SLASHING ELECTRONIC/PCBA NPI TIME

Following a simple but decisive and forward thinking approach called “Five Steps to Slashing Electronic/PCBA NPI Time” will show significant reduction in New Product Introduction (NPI) time in the PCBA phase of product development.

Even if “time is not of essence” in your NPI utilizing this approach will show positive reduction in cost and improve quality because it cuts out wasted time.

Five Steps to Reduce NPI Time:

1. Following a method to identify and track “Critical Path” elements in the development cycle.

2 & 3. Eliminating queue and wait time for quoting and issuing of PO’s.

4. Preventing mfg. delays – information control.

5. Processing/mfg. in parallel rather than in-series.

Details for reducing NPI time:

1. Following a method to identify and track “Critical Path” elements in the development cycle.

This method actually has two facets implemented during the design (schematic development) phase:

a. Identifying critical path components and materials for availability. Engineers typically know the critical and unique components in their design. This action is listed “first in importance”, as long lead times on components and materials typically create the most significant impact on delays. In the case of electronic components it is as simple as checking availability on a website like: www.eciaauthorized.com, then taking the appropriate action (purchasing, changing, verifying, etc.) based on the results of your search.

b. Utilize a check sheet detailing each phase/step in the process of producing the assembly or box build: Design, schematic, BOM (Bill of Materials) creation, PC Board layout, files and documentation creation, bare board fab, procurement of parts and materials, and assembly. This process identifies early issues effecting lead-time and cost. Once issues are identified (technology, components, materials, tolerances, requirements, etc.) they can be addressed as needed. Development of this check sheet is an easy process. Just do this over time and you gain experience. Another option is just request our standard format then tailor to your needs.

An important part of this process is getting your supplier involved early in a project. This is especially true if unique or difficult challenges exist. Results will include: lower cost and faster delivery, particularly if non-standard processing or material is involved.

2 & 3. Eliminating queue and wait time for quoting and issuing PO’s.

The process of designing, quoting, and mfg. PCBA’s is typically done in a sequential manner. Simply changing the timing of attaining quotes and PO’s as a parallel process can “completely” remove this delay. In many cases this time takes as long as mfg. itself.

Quoting and issuing of PO’s can easily be completed in the prior stage. Example: Bare boards and assembly quotes and PO’s can be completed during the Layout process. Worst case adjustments can be made when the final version files are created.

Additionally, particularly for frequent flyer companies (many prototypes); a quote matrix can be developed and utilized for products and services. This foregos the need to quote each board, accept for its unique components and that saves time.

4. Preventing mfg. delays – information control.

Quality and complete information is “King”. Providing your supplier with the complete information needed to quote or run product will reduce or eliminate delays. Sounds basic but nearly half of all prototype orders have questions and issues that delay jobs from moving forward. Most of these can be eliminated by having a standard system that is followed for all documentation. A check list, easy to develop over time, should be used. Also we can provide our standard form for you to modify for your particular requirements.

Key also is providing schematics, files, documentation, etc., that are compatible with your supplier’s systems/software platforms. Communicating up front will and prevent delays and redundant work.

5. Processing/manufacturing in-parallel rather than in-series.

Lastly: Components and materials should be ordered by your supplier prior to or at the time the PC Bare Board Mfg. starts. This will certainly insure components and materials are available for assembly when the PC Bare Boards are complete. Utilizing a company controlling the entire process: layout thru. assembly will provide the added benefit of single source accountability, improved delivery, and performance.

Summary: Following the 5 Key Steps to Slashing NPI time saves both time and money. It creates the option to get deliveries in historic timeframes at reduced costs or more importantly significantly faster for the same cost.

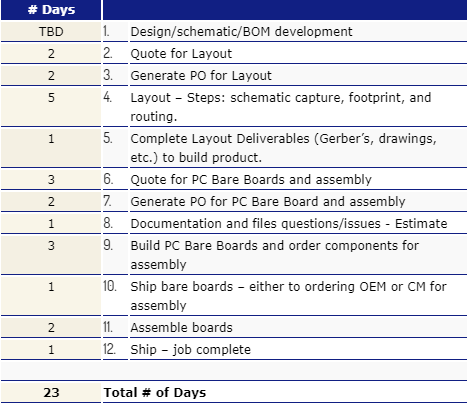

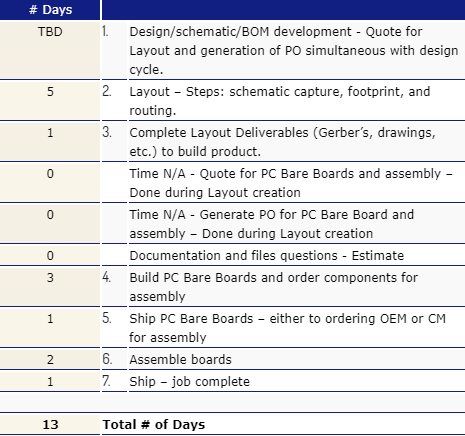

Below is a comparison of thru-put times following Standard Industry Methods vs. Best Practices following the 5 Steps to reducing NPI times.

Example Typical Standard NPI time for PCBA’s:

Example Utilizing Five Steps to reduce NPI time for PCBA’s:

In this typical example: Saving 10 Days, 43% reduction in time.

In an example of an even quicker turn time it would not be unusual to see a 50% reduction in time because best practices are followed.

Conclusion: It pays to plan out and control your NPI Process – end result: Getting your product to the market place first.

CERTIFIED IS09001

SBC is an ISO 9001:2015 certified company through UL-DQS. South Bay Circuits utilizes ISO 9001:2015 eight fundamental quality management principles to help improve our PC Board Fab, PC Assembly, and Box Build performance. Certificate #: 10000903 QM15

ITAR REGISTRATION

ITAR Registered! We are a manufacturer that builds defense articles with related technical data that can be defined on the United States Munitions List (Part 121 of the ITAR), where we are registered.