PCB DESIGN SERVICES

Team with South Bay Circuits (SBC), a Single Source Electronic CM offering “World Class” services to OEM’s and PCB Designers for your PCB Design, Layout, and Mfg. needs. We take your “Design Circuit Board Concept” and turn it into a complete and functioning product offering PC Board Manufacturing and PC Board Assembly Service capabilities, as you need.

SBC uniquely offers capabilities in Product PCB Design as well as Mfg. of Finished Products utilizing our “World’s Quickest” Service. Within our 60K sq. ft. facilities SBC can transition your product seamlessly from PC Board Prototype to full production.

SBC Senior PCB Design Team

Our team has completed hundreds of PCB Designs in a wide range of electronic product technologies. Working with a team that controls the “entire process” from Product Concept through “Complete PC Board Assembly” or “Full Box Build” helps insure success of your design and product. SBC’s “start to finish” capabilities insures manufacturability, best costs, and product reliability at lightning speed in your product development, prototyping, pre-production, and production runs.

Our experienced PCB designers work closely with your engineering team offering insight and creative methods to develop your product concept into reality.

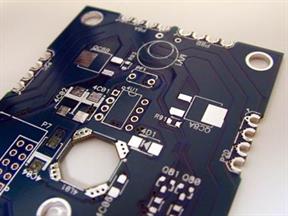

PC Board Layout and Mechanical Design

SBC offers a multitude of capabilities to take your schematic, or the PCB Design we developed with your team, and create the tools, software, and documentation to turn your idea into a finished product. Layout is the first production step. We support PCB Designs from low cost to HDI technology including: High layer counts, controlled impedance, mixed technologies, digital or power boards, standard technologies, BGA or Micro BGA’s, high speed or high voltage designs, and ITAR and RoHS compliant designs.

We offer a wide variety of PCB Design and PC Board Layout Platforms including: PCAD, PADS (Mentor Graphics), Altium Designer, and Cadence Allegro to insure compatibility with your systems and to provide flexibility to meet any design/layout challenge.

SBC also provides a complete set of deliverables with each job. These meet or exceed industry standards including: IPC Netlist, Assembly Drawings, Updated “Bill of Materials” (BOM), Fabrication Drawings, Pick & Place (PNP) Data, Gerber Data, and Drill Data in Excellon Format. These tools allow you to keep complete and up-to-date documentation to build your product now and in the future.

Team with SBC, a partner committed to your “Circuit Board Design” success.

SBC Building Your PCB Design and PC Board Layout – Taking the Next Step

Once SBC has completed your PCB Design and PC Board Layout we can proceed with the PC Board manufacturing and Printed Circuit Board Assembly in as little as 48 hours, right in the same facility. We provide the fastest turn in the industry through the benefit of having complete control of all processes and steps: PCB Design, PC Board Layout, PC Board Fabrication, and PC Board Assembly at our 120,000 square foot facility in Chandler AZ. Being under one roof eliminates delays caused in transferring files and shipping and delivering product. These delays are often as much or more than the actual time to turn at each step: PCB Design, PC Board Layout, PC Board Fabrication, and PC Board Assembly.

For PC Board Layout and PCB Design guidelines and PC Board Manufacturing and PC Board Assembly consult the below documents:

SBC Manufacturability Guidelines for Printed Circuit Boards (PDF)

CERTIFIED IS09001

SBC is an ISO 9001:2015 certified company through UL-DQS. South Bay Circuits utilizes ISO 9001:2015 eight fundamental quality management principles to help improve our PC Board Fab, PC Assembly, and Box Build performance. Certificate #: 10000903 QM15

ITAR REGISTRATION

ITAR Registered & CMMC Level 1! We are a manufacturer that builds defense articles with related technical data that can be defined on the United States Munitions List (Part 121 of the ITAR), where we are registered and meets the reqirements of CMMC Level 1.